Six Sigma Process

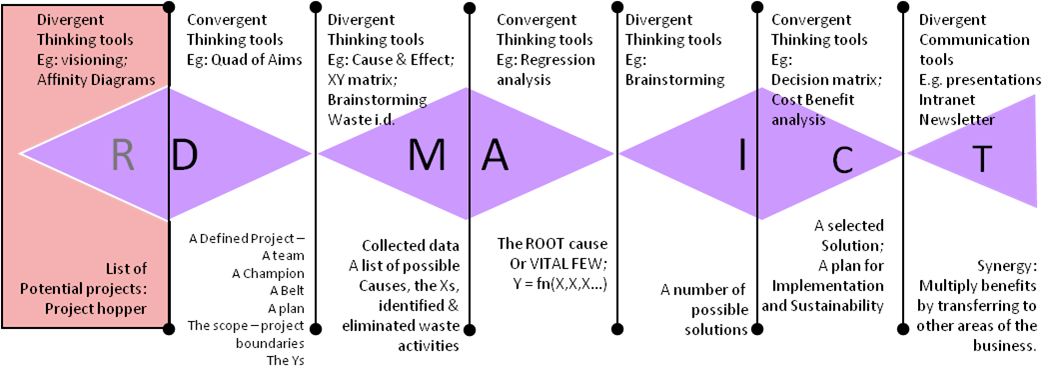

DMAICT for existing products and processes Six Sigma provides a rigorous methodology for identifying and addressing the causes of variation in a process. That methodology incorporates a series of phases abbreviated to DMAICT, with a prior project selection phase (Recognise):

RECOGNISE: Identify where output variation is hurting the customer

DEFINE: Form the project team and scope the opportunity

MEASURE: Identify the potential causes of variation in the process and collect data on them

ANALYSE: Evaluate the data to identify the true root causes of variation

IMPROVE: Address those root causes by creating and implementing suitable solutions

CONTROL: Establish the necessary ongoing control actions to sustain the improvement

TRANSFER: Share lessons learnt across the organization to maximise the benefits

Delivering Six Sigma projects requires more than just a methodology. It requires a comprehensive set of best practice process improvement tools and people with the right skills to drive success.